Inspection

What is a Product Quality Inspection?

When you’re making consumer products at a factory overseas, it can be hard to judge the quality of your products before you actually receive them.

So, third-party companies (Like Insight) help you get a look at the condition of your products while they’re still at the factory. They’ll send inspectors to check on your order before, during, or after production.

The checks are performed to help verify whether the products meet your quality requirements, are in compliance with regulations, and meet any relevant product safety standards.

Here you can see some furniture pieces being lined up for inspection…

The most common type of quality inspection we perform is called a PSI or Pre-Shipment Inspection.

These are also referred to and Final Random Inspections. And, although they are the most common, there are other types of inspections you should be familiar with too.

Each type of inspection happens at a different point in the manufacturing process. We’ll look at them in order.

What is a Pre-shipment inspection or Final Random Inspection?

It is an on-site Product Inspection that monitors the conformity of production to your

specifications. This will ensure your products are consistent and compliant with all

country, industry or otherwise-specified requirements and that no critical major or minor

defects appear.

These inspections are conducted once raw materials have been received by the factory. They can help you to verify that the materials being used meet your standards. They can also be done to help you check a prototype or ensure that the factory is ready for production.

These are conducted once 20% of your products have been completed. Conducting inspections at this early stage allows you to identify issues sooner. It also helps you to avoid delays later on in the process. If you’re producing large volumes or are in a time crunch, these can be ideal.

These are the most common inspections that importers hire us to conduct. They are done when 100% of your products are complete and at least 80% are packaged. They allow you to verify quality and ensure that the finished products are up to your specifications before they are shipped to you.

A major overhaul in any type of production process is necessary for quality deliverables. Final Random Inspection (FRI), also known as Finished Quality Control (FQC) is one of the most critical processes that is like a finishing touch to the entire quality control system. This is done when the order is ready to go. So what makes this process so crucial for Quality Control? Read on.

1. To identify critical and minor defects

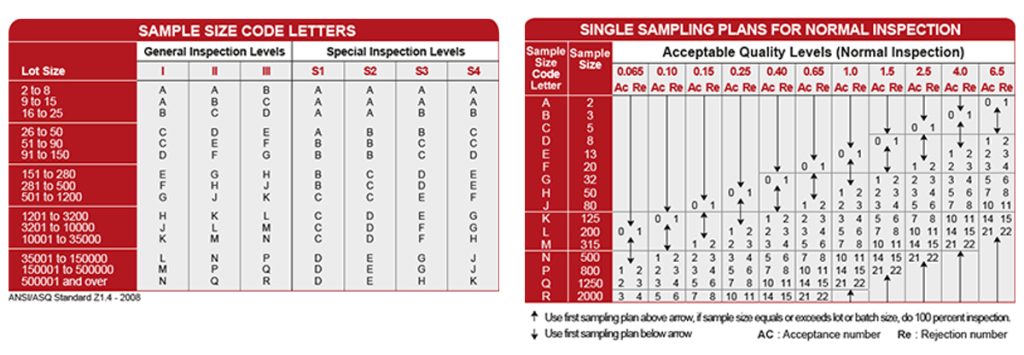

The inspector needs to assess the Acceptable Quality Level (AQL) of the products before giving it a final go. The assessment is based on the severity of defects in a product. When a product is detected with a ‘critical’ or ‘major’ defect those are marked as unfit to move further. Products that are detected with ‘minor’ defects might not be regarded as unfit for shipment, but they might be considered for rectification.

2. To list all specifications

Quality Control listing encompasses an array of specifications of the products including size, quantity, assembly, appendages, labelling, packaging, etc. The inspector is given this checklist, and he needs to have a final review of all the specifications and then do the reporting accordingly.

3. To check on-site performance testing

In some cases, the inspector needs to perform additional tasks of checking the specific type of products. FRI includes on-site performance testing of such products to ensure high-quality assurance.

4. To detect overlooked features

When the products are prepped for FRI, it is expected that those have already undergone rigorous checking processes. FRI involves superficial scanning of the products where the inspector may detect things that are overlooked during the earlier Quality Control processes.

5. To avoid late delivery

If the products are detected with anomalies after the shipment process, then those have to be sent back again for rectification or reworking. FRI is necessary to avoid this delay and incorporate timely delivery to the purchasers.

6. To maintain good reputation of the manufacturers

The product purchasers will always expect high-quality deliverables from the manufacturers. If they are not happy with the deliverables, then they might consider rethinking about the final pricing. FRI is important to provide ‘Quality checked’ products in order to maintain the reputation of the manufacturers.

7. To authorize shipment

An FRI is like giving a clean chit to the production and authorization of shipment ensues based on this report. After the delivery, the products will be ready to hit the market.

8. To enable efficiency in packaging

The packaging of the products can be prepped efficiently based on the FRI report. Final Random Inspection is considered to be the most popular QC service in China. If you have a business that deals with consumer goods, then you can consider FRI and other Quality Control systems for high-quality products. Do some research and get in touch with the leading inspection company in China which will provide a wide range of Quality Control solutions like Initial production checking, During Production Checking (DUPRO), final random inspection, loading supervision, and other similar services to deliver the best quality products.

A major overhaul in any type of production process is necessary for quality deliverables. Final Random Inspection (FRI), also known as Finished Quality Control (FQC) is one of the most critical processes that is like a finishing touch to the entire quality control system. This is done when the order is ready to go. So what makes this process so crucial for Quality Control? Read on.

1. To identify critical and minor defects

The inspector needs to assess the Acceptable Quality Level (AQL) of the products before giving it a final go. The assessment is based on the severity of defects in a product. When a product is detected with a ‘critical’ or ‘major’ defect those are marked as unfit to move further. Products that are detected with ‘minor’ defects might not be regarded as unfit for shipment, but they might be considered for rectification.

2. To list all specifications

Quality Control listing encompasses an array of specifications of the products including size, quantity, assembly, appendages, labelling, packaging, etc. The inspector is given this checklist, and he needs to have a final review of all the specifications and then do the reporting accordingly.

3. To check on-site performance testing

In some cases, the inspector needs to perform additional tasks of checking the specific type of products. FRI includes on-site performance testing of such products to ensure high-quality assurance.

4. To detect overlooked features

When the products are prepped for FRI, it is expected that those have already undergone rigorous checking processes. FRI involves superficial scanning of the products where the inspector may detect things that are overlooked during the earlier Quality Control processes.

5. To avoid late delivery

If the products are detected with anomalies after the shipment process, then those have to be sent back again for rectification or reworking. FRI is necessary to avoid this delay and incorporate timely delivery to the purchasers.

6. To maintain good reputation of the manufacturers

The product purchasers will always expect high-quality deliverables from the manufacturers. If they are not happy with the deliverables, then they might consider rethinking about the final pricing. FRI is important to provide ‘Quality checked’ products in order to maintain the reputation of the manufacturers.

7. To authorize shipment

An FRI is like giving a clean chit to the production and authorization of shipment ensues based on this report. After the delivery, the products will be ready to hit the market.

8. To enable efficiency in packaging

The packaging of the products can be prepped efficiently based on the FRI report. Final Random Inspection is considered to be the most popular QC service in China. If you have a business that deals with consumer goods, then you can consider FRI and other Quality Control systems for high-quality products. Do some research and get in touch with the leading inspection company in China which will provide a wide range of Quality Control solutions like Initial production checking, During Production Checking (DUPRO), final random inspection, loading supervision, and other similar services to deliver the best quality products.

A major overhaul in any type of production process is necessary for quality deliverables. Final Random Inspection (FRI), also known as Finished Quality Control (FQC) is one of the most critical processes that is like a finishing touch to the entire quality control system. This is done when the order is ready to go. So what makes this process so crucial for Quality Control? Read on.

1. To identify critical and minor defects

The inspector needs to assess the Acceptable Quality Level (AQL) of the products before giving it a final go. The assessment is based on the severity of defects in a product. When a product is detected with a ‘critical’ or ‘major’ defect those are marked as unfit to move further. Products that are detected with ‘minor’ defects might not be regarded as unfit for shipment, but they might be considered for rectification.

2. To list all specifications

Quality Control listing encompasses an array of specifications of the products including size, quantity, assembly, appendages, labelling, packaging, etc. The inspector is given this checklist, and he needs to have a final review of all the specifications and then do the reporting accordingly.

3. To check on-site performance testing

In some cases, the inspector needs to perform additional tasks of checking the specific type of products. FRI includes on-site performance testing of such products to ensure high-quality assurance.

4. To detect overlooked features

When the products are prepped for FRI, it is expected that those have already undergone rigorous checking processes. FRI involves superficial scanning of the products where the inspector may detect things that are overlooked during the earlier Quality Control processes.

5. To avoid late delivery

If the products are detected with anomalies after the shipment process, then those have to be sent back again for rectification or reworking. FRI is necessary to avoid this delay and incorporate timely delivery to the purchasers.

6. To maintain good reputation of the manufacturers

The product purchasers will always expect high-quality deliverables from the manufacturers. If they are not happy with the deliverables, then they might consider rethinking about the final pricing. FRI is important to provide ‘Quality checked’ products in order to maintain the reputation of the manufacturers.

7. To authorize shipment

An FRI is like giving a clean chit to the production and authorization of shipment ensues based on this report. After the delivery, the products will be ready to hit the market.

8. To enable efficiency in packaging

The packaging of the products can be prepped efficiently based on the FRI report. Final Random Inspection is considered to be the most popular QC service in China. If you have a business that deals with consumer goods, then you can consider FRI and other Quality Control systems for high-quality products. Do some research and get in touch with the leading inspection company in China which will provide a wide range of Quality Control solutions like Initial production checking, During Production Checking (DUPRO), final random inspection, loading supervision, and other similar services to deliver the best quality products.

What happens if you discover an issue that affects a significant percentage of your units? Conducting a sort inspection allows you to separate out any defective units and get an exact count of the good ones. This way you can move forward with only the acceptable products.

Understanding these 5 types of inspections puts you in a better position to choose the right one for your situation.